Secutex® is a single-layered, mechanically bonded, nonwoven geotextile

Some products are additionally calendered. Secutex® is used for the separation of soil layers with different grain sizes as well as to establish the missing filter stability.

Typical solutions with Secutex®

Advantages of Secutex®

Selected advantages of Secutex® multifunctional geotextile

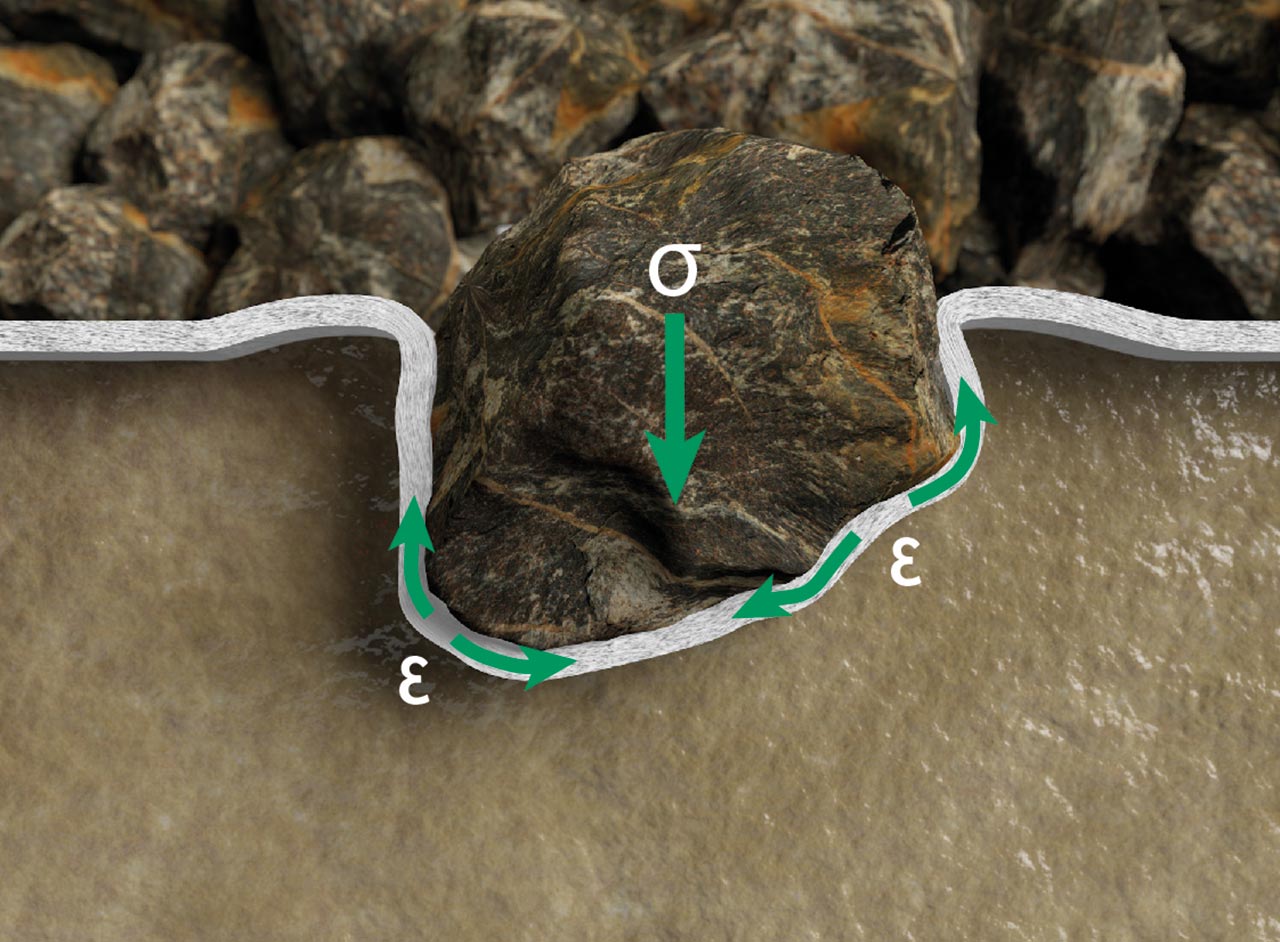

Site condition and stress/strain impact on Secutex® nonwoven. σ = Load on stone / ε = Strain

Advantage 1: High elongation capacity ensures excellent resistance to damage

When applying additional earth layers over a soil with a poor bearing capacity, the elongation characteristics of the nonwoven geotextile will minimise damage during the installation process. To ensure the separation function under high rutting, Secutex® nonwoven geotextiles with high elongations are the first choice. The high elongation capacity of Secutex® nonwoven geotextiles ensures excellent resistance to damage.

This characteristic of Secutex® products allows them to easily accommodate irregular or soft sub-grades. Especially when covered with stone material, Secutex® nonwoven geotextile fibres are reoriented around the stones, preventing damage to the nonwoven structure.

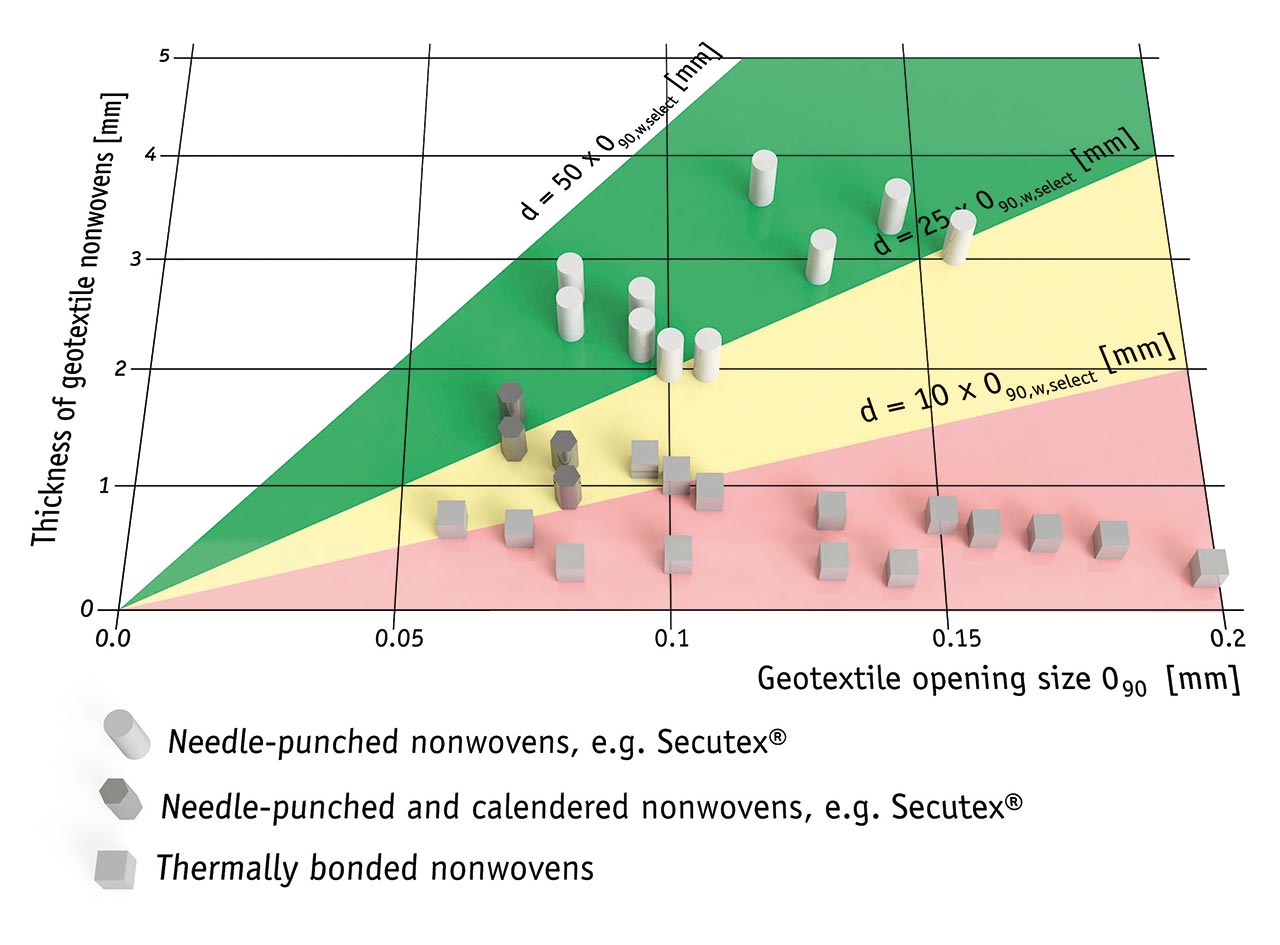

Recommended opening size and thickness correlation (range: green – recommended; yellow – application-related possible; red – critical) for a filter geotextile (DWA-M 511, 2017)

Advantage 2: Long-term filter effectiveness

As with mineral filter layers, soil retention capacity also plays an important role when using Secutex® nonwoven geotextiles. Geotextile filters must be engineered such that the mechanical effectiveness and hydraulic filter effectiveness (water discharge without loss of pressure) are equally achieved.

Unique to the manufacturing process, needle-punched Secutex® nonwovens can be produced in greater thicknesses than other bonded nonwovens. Hence they can be produced in compliance with the recommended minimum geotextile thickness [d] of 25 · O90 < d < 50 · O90 („DWA-M 511, 2017“) thereby ensuring the long-term filter effectiveness of the non-woven.